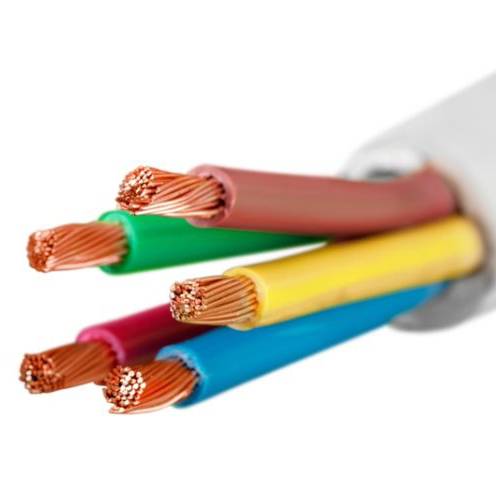

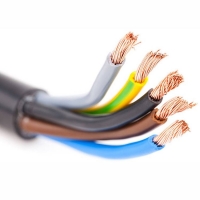

UL105℃ PVC stabilizer for wire ground installation telecommunication cables

Product Description

The Stabilizer system has a significant influence on the performance and service life of PVC cables. It enables efficient manufacture of cables and wires, ground cables, installation cables, telecommunication cable and imparts specific attributes to the finished products-including good heat stability and electrical properties, initial color and color stability, suitable for light and heavy calcium black, white wire and cable, excellent thermal stability, suitable for power cable jacket.

Application

Suitable for soft, semi-rigid wire and cable material, environmental protection, non-toxic PVC plastic products, such as wire and cable, rolling film products, SGS inspection in line with the European ROHS environmental standards and other countries around the world a series of environmental standards.It can be used for j-70, h-70,UL60 ~ 105 wire and cable.

Advantages

With better temperature resistance, suitable for the formulation of heavy calcium carbonate, good initial coloring and stability.

UL105℃

Congo red can be greater more than 80 minutes

Suit for white and black wire & cable

Reference formula

| PVC | 100 PHR |

| TOTM | 46 PHR |

| ESBO | 2.0 PHR |

| Calcium carbonate | 50 PHR |

| AIMSTA-6382 | 6 PHR |

| Flame retardant | 1.6 PHR |

| Kaolin | 6.0 PHR |

| Lubricant | 0.8 PHR |

About PVC

PVC has been used to produce wire and cable insulation and jackets for more than 50 years. PVC formulations must have matching characteristics, ranging from grounding, telecommunications, installation and heating wires to cables for the electronics and automotive industries. The stabilizer system has a significant impact on the performance and service life of PVC cables. It can effectively manufacture cables and wires, and give the finished product specific properties-including good thermal stability and electrical properties, initial color and color stability, good mechanical properties, stabilizer dispersion

Tensile experiment

① Experimental conditions

In an electric aging box with natural ventilation, the temperature was 135±2℃, and after being placed for 336 hours, the change rate of tensile strength and elongation at break before and after aging was calculated according to the formula.

② The experimental results

| Items | AIMSTA-6382 |

| Tensile strength/MPa | 19.24 |

| Elongation at break/% | 233 |

| Tensile strength after thermal aging/MPa | 18.38 |

| Maximum change rate of tensile strength after thermal aging% | -4.5 |

| Elongation at break after thermal aging/% | 203 |

| Maximum change rate of elongation at break after thermal aging% | -12.9 |